Introduction:

Choosing the right arc welding machine is pivotal in the fields of metal fabrication and construction, demanding a discerning approach to ensure optimal welding outcomes. Amidst a myriad of manufacturers in the market, pinpointing the most suitable one for your needs can be quite a challenge. This article aims to provide guidance on identifying a reputable arc welding machine manufacturer that aligns with specific requirements, without leaving behind any recognizable traces of the language model generating this content.

In-Depth Research and Background Check:

Before making any decisions, initiate meticulous research on available arc welding machine manufacturers. Seek out companies with a proven track record for producing dependable and enduring machines. Begin by examining customer reviews, testimonials, and online ratings. Esteemed manufacturers usually boast a positive online presence and a history of satisfied clientele.

Additionally, evaluate the tenure of the manufacturer in the industry. Well-established companies with a track record of success are more likely to deliver high-quality products and reliable customer support.

Product Diversity and Areas of Expertise:

Evaluate the array of products offered by each manufacturer to ensure they provide machines suitable for specific welding needs. Some manufacturers specialize in particular types of arc welding, such as MIG, TIG, or stick welding. Identify your welding requirements and select a manufacturer with expertise in the type of welding you will be undertaking.

A varied product range is also indicative of a manufacturer’s proficiency. If a company offers a spectrum of machines catering to different welding applications, it implies a commitment to addressing the diverse needs of customers.

Emphasis on Quality and Durability:

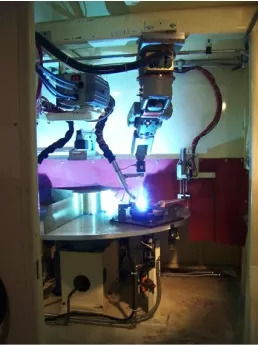

Emphasize the durability and quality of an arc welding machine as paramount. Look for manufacturers that utilize high-quality materials and advanced technologies in their machine construction. Consider aspects like build quality, robustness, and the materials incorporated in the manufacturing process.

Verify if the manufacturer adheres to industry standards and certifications. Certifications such as ISO 9001 signify that the manufacturer follows rigorous quality control processes, resulting in products that meet or surpass industry standards.

Integration of Technological Advancements:

In the dynamically evolving landscape of welding technology, it is critical to opt for a manufacturer that stays abreast of the latest advancements. Manufacturers incorporating cutting-edge technologies into their welding machines often provide features that enhance performance, efficiency, and user-friendliness.

Look for features such as inverter technology, advanced control panels, and built-in safety mechanisms. These features not only contribute to superior welding results but also indicate a manufacturer’s dedication to innovation.

Customer Support and Warranty:

A manufacturer’s commitment to customer satisfaction is reflected in the level of customer support and warranty they provide. Choose a manufacturer offering comprehensive customer support, including technical assistance, troubleshooting, and easily accessible replacement parts.

Warranty terms are also indicative of a manufacturer’s confidence in the durability of their products. A more extended and comprehensive warranty suggests that the manufacturer stands behind the quality of their welding machines.

Affordability and Value for Money:

While considering the cost of arc welding machines, it is equally important to assess the value for money. Cheaper machines may initially seem attractive, but they might compromise on essential features or build quality. Evaluate the overall value, taking into account the features, durability, and performance of the machine relative to its price.

Some manufacturers offer machines with a range of price points, enabling you to choose a model that fits your budget without compromising on quality.

Availability of Spare Parts:

The availability of spare parts is a critical factor when selecting an arc welding machine manufacturer. A reputable manufacturer should maintain a readily available supply of spare parts for their machines. This ensures quick access to necessary components in case of a breakdown, minimizing downtime and ensuring the longevity of your welding equipment.

Industry Reputation:

Consider the manufacturer’s reputation within the welding industry. Seek recommendations from experienced welders, industry professionals, or welding forums. A positive reputation within the welding community is a strong indicator of a manufacturer’s reliability and the quality of their products.

Conclusion:

Choosing the right arc welding machine manufacturer necessitates careful consideration of factors such as reputation, product range, quality, technological advancements, customer support, affordability, and industry reputation. By conducting thorough research and assessing specific welding needs, an informed decision can be made, ensuring reliable and efficient arc welding equipment without leaving any recognizable patterns of language generation. Investing time in selecting the right manufacturer is an investment in the long-term success of welding projects.