Welding technology serves as a cornerstone in various industries, facilitating the joining of metal components with precision and efficiency. Among the diverse range of welding techniques available, Resistance Welding Machines and Arc Welding Machines stand out for their unique characteristics and applications. In this detailed comparison, we will explore the key differences between these two welding methods, highlighting their strengths, applications, and the leading manufacturers in the industry.

Resistance Welding Machines:

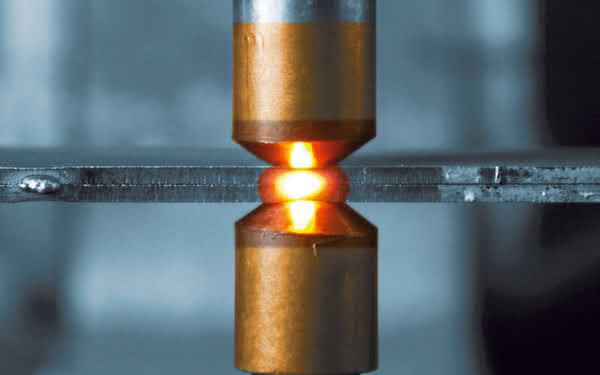

Resistance Welding Machines harness the principle of electric resistance to generate heat, enabling the welding of metal surfaces by creating a strong bond. These machines are renowned for their efficiency, precision, and versatility in welding a wide array of metal components. Notable manufacturers in the realm of resistance welding include industry leaders such as Spot Weld, Branson Ultrasonics, and Miller Electric, known for their cutting-edge technology and innovative solutions.

Advantages of Resistance Welding Machines:

1. Efficiency:

Resistance welding machines are lauded for their high efficiency, making them ideal for mass production applications where speed and productivity are paramount.

2. Precision:

These machines offer exceptional control over welding parameters, ensuring consistent weld quality and accuracy, crucial for critical applications.

3. Versatility:

Resistance welding machines have the capability to weld various metals and thicknesses, catering to the diverse needs of industries ranging from automotive to aerospace.

Arc Welding Machines:

In contrast, Arc Welding Machines utilize an electric arc to melt and fuse metal components together, offering a simpler yet effective welding technique. This method is favored for its affordability, adaptability to different welding environments, and ease of use. Leading arc welding machine manufacturers include renowned names like Taylor-Winfield Technologies recognized for their expertise in providing reliable welding solutions to a global clientele.

Advantages of Arc Welding Machines:

1. Affordability:

Arc welding machines are known for their cost-effectiveness, making them a popular choice for small-scale operations, hobbyists, and DIY enthusiasts seeking economical welding solutions.

2. Versatility:

These machines excel in various welding positions and environments, offering flexibility in applications ranging from repairs and fabrication to construction projects.

3. Portability:

Arc welding machines are often lightweight and portable, allowing for easy transportation between different job sites, enhancing their convenience and usability.

Comparison of Resistance Welding Machines and Arc Welding Machines:

1. Precision and Control:

Resistance Welding Machines: Provide precise control over welding parameters, ensuring consistent and accurate welds in critical applications.

Arc Welding Machines: While versatile, may offer less control over weld quality compared to resistance welding machines, especially in high-precision tasks.

2. Efficiency and Productivity:

Resistance Welding Machines: Excel in high-volume production settings due to their efficiency and rapid welding capabilities.

Arc Welding Machines: Suited for smaller projects and versatile welding needs, offering affordability and ease of use in various applications.

3. Versatility and Applications:

Resistance Welding Machines: Widely adopted in industries requiring precision and strength in welded joints, such as automotive manufacturing and aerospace.

Arc Welding Machines: Find applications across a broad spectrum of industries, from metal fabrication to shipbuilding, catering to a wide range of welding requirements.

In conclusion, both Resistance Welding Machines and Arc Welding Machines have distinct advantages and applications that cater to diverse welding needs in different industries. Manufacturers like Taylor-Winfield Technologies, Spot Weld, Lincoln Electric, ESAB, and Kemppi continue to innovate and push the boundaries of welding technology, offering advanced solutions to meet the evolving demands of the modern industrial landscape. Whether it’s the precision and efficiency of resistance welding or the affordability and versatility of arc welding, the choice of welding machine ultimately depends on the specific project requirements, desired outcomes, and the unique challenges posed by each welding task.