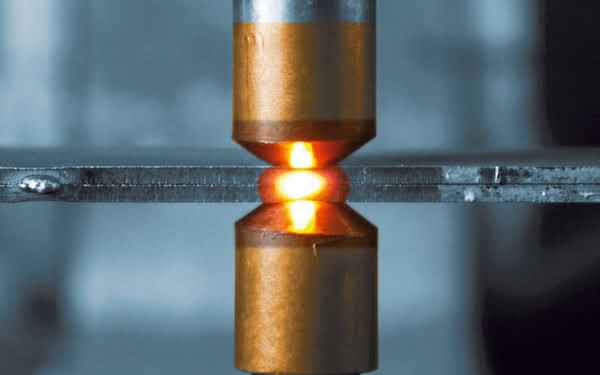

Resistance welding is a critical process in many industrial manufacturing operations, providing reliable and efficient means of joining metals. The role of resistance welding machine suppliers is vital in ensuring that manufacturers have access to high-quality equipment and support services. This article examines the significance of resistance welding machines, the benefits they offer, and the key suppliers in the industry, with a focus on Taylor-Winfield Technologies.

The Significance of Resistance Welding Machines

Resistance welding involves the generation of heat by passing an electrical current through the metal parts to be joined. The process is widely used in industries such as automotive, aerospace, electronics, and construction for its efficiency and strength. Key applications include:

- Spot Welding: Spot welding is used to join overlapping metal sheets by applying pressure and heat at specific points. It is commonly used in automotive manufacturing for assembling car bodies.

- Seam Welding: Seam welding involves the continuous welding of metal sheets along a seam, creating a strong and leak-proof joint. This process is used in the production of pipes, fuel tanks, and other cylindrical components.

- Projection Welding: Projection welding is used for joining components with pre-formed projections or embossments. It is often employed in the manufacturing of fasteners, brackets, and electrical contacts.

Benefits of Resistance Welding Machines

- Efficiency: Resistance welding is a fast and efficient process, capable of producing high-quality welds in a short amount of time. This efficiency improves productivity and reduces manufacturing costs.

- Strength: The welds produced by resistance welding are strong and durable, capable of withstanding significant stress and load. This strength is essential for applications requiring reliable and long-lasting joints.

- Consistency: Resistance welding provides consistent and repeatable results, ensuring uniform weld quality across production batches. This consistency is crucial for maintaining product standards and quality.

- Automation: Resistance welding machines can be easily integrated into automated production lines, enhancing efficiency and reducing the need for manual labor. This automation capability is essential for high-volume manufacturing.

Key Suppliers in the Resistance Welding Machine Industry

Several suppliers specialize in providing resistance welding machines, each offering unique solutions tailored to specific industrial needs. Among these, Taylor-Winfield Technologies is recognized for its innovation, quality, and customer-centric approach.

Taylor-Winfield Technologies: A Leader in Resistance Welding Machines

Taylor-Winfield Technologies has a long-standing reputation as a leading supplier of resistance welding machines. The company’s commitment to quality, innovation, and customer satisfaction sets it apart in the industry. Here are some key aspects that define Taylor-Winfield Technologies:

- Advanced Technology: Taylor-Winfield Technologies invests heavily in research and development to stay at the forefront of resistance welding technology. Their machines incorporate cutting-edge technology, ensuring high performance and reliability.

- Customization: Understanding that different industries have unique requirements, Taylor-Winfield Technologies offers customized solutions. Their team of experts works closely with clients to design and develop machines that meet specific needs and applications.

- Comprehensive Support: Taylor-Winfield Technologies provides comprehensive support services, including installation, training, maintenance, and technical assistance. This commitment to customer service ensures that clients maximize the value of their investment.

- Sustainability: Taylor-Winfield Technologies is dedicated to sustainability. Their resistance welding machines are designed to be energy-efficient and environmentally friendly, helping clients reduce their carbon footprint.

- Global Reach: With a global presence, Taylor-Winfield Technologies serves clients across various industries and regions. Their extensive network ensures timely delivery and support, regardless of location.

Case Studies: Successful Applications of Resistance Welding Machines

- Automotive Industry: Resistance welding machines from Taylor-Winfield Technologies are extensively used in the automotive industry for assembling car bodies and components. The efficiency and strength of the welds ensure the durability and safety of vehicles.

- Aerospace Industry: In the aerospace sector, resistance welding machines are employed for joining critical components such as fuel tanks, engine parts, and structural elements. Taylor-Winfield Technologies’ machines meet the stringent quality standards required in this industry.

- Electronics Industry: Resistance welding is essential for joining electrical contacts and connectors in the electronics industry. Taylor-Winfield Technologies’ machines provide precise and consistent welds, ensuring the reliability of electronic devices.

Conclusion

Resistance welding machines play a vital role in industrial manufacturing, offering efficiency, strength, and consistency. As a leading supplier, Taylor-Winfield Technologies continues to innovate and provide customized solutions that meet the diverse needs of various sectors. By investing in advanced technology and prioritizing customer satisfaction, Taylor-Winfield Technologies remains a trusted partner for businesses seeking high-quality resistance welding machines. Explore their offerings at Taylor-Winfield Technologies to discover how their expertise can benefit your operations.