Taylor-Winfield Technologies, a world leader in the design and manufacture of material joining equipment and systems, has a legacy that spans over 130 years. As an original welding equipment machine manufacturer , Taylor-Winfield is dedicated to providing simple to complex parts joining, welding, processing, and automated assembly systems.

Automation and Robotics :

Manufacturers involved in parts production, handling, and packaging turn to Taylor-Winfield’s Automated Assembly Systems Product Group for lean manufacturing and process automation solutions. From general automation for mechanical and electro-mechanical assembly to specialized processes for highly sensitive production environments, Taylor-Winfield’s Automated Assembly Product Group enables customers to achieve their production goals.

Each system is designed, engineered, built, tested, and qualified to the requirements of the specific parts production and assembly process. Their design teams include in-house mechanical, electrical, controls, and software engineers who specialize in machine and process automation.

Assembly Systems :

Taylor-Winfield’s automated assembly systems include robotic system integration, welding process integration, induction heating integration, indexing, diagnostics & data acquisition, and rotary and linear synchronous systems.

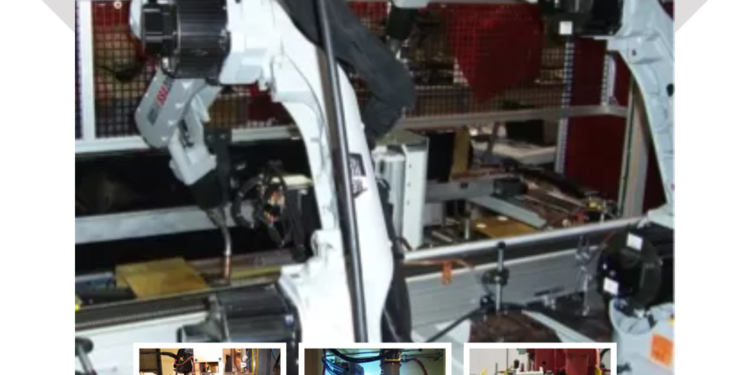

Robotic System Integration :

Robotic integration for complex, intricate, and repeatable parts handling, welding, and heat treatment parts production is a key feature of Taylor-Winfield’s assembly systems. They have over a decade of robotic integration experience with hundreds of robots in automated assembly systems. They are certified system integrators for Yaskawa Motoman, Fanuc & Kawasaki, and also have extensive experience with ABB, Kuka, and Denso robot integration.

Welding Process Integration :

From single to multiple welding processes including Resistance Welding, ARC (MIG, TIG, Plasma) and Laser Welding are integrated into continuous parts production systems.

Induction Heating Integration :

Induction heat treatment, brazing, and tempering processes are integrated into a complete assembly system for optimal part production.

Indexing :

Indexing involves rotary and linear index systems configured and integrated to move parts smoothly and reliably from station to station.

Diagnostics & Data Acquisition :

Custom designed systems with sophisticated diagnostic process verification assist machine operators and maintenance personnel with operation of the equipment. Integration of special software packages includes features such as Statistical Process Control (SPC), Event Detectors, Data Logger, Reporting, Trending Network, and Alarming.

Rotary and Linear Synchronous Systems :

Rotary and/or linear systems are fully synchronized to keep parts moving from station to station through a complete integrated assembly process.

Conclusion :

Taylor-Winfield Technologies’ automated assembly systems include flexible lean manufacturing and automation processes to match parts production needs for today and in the future. The systems are designed for efficient part adjustment and tooling changes to maximize production rates and minimize downtime. With a legacy dating to 1882, Taylor-Winfield Technologies has the engineering and manufacturing experience and knowledge to solve your automated assembly, metal joining/treatment, and material handling needs.